- Joined

- Jul 9, 2023

- Messages

- 109

GitHub, with PDF Schematic and Arduino code: GitHub - travis-farmer/ard_shop_automation: the MQTT automation shop controller project (https://github.com/travis-farmer/ard_shop_automation)

the controller will monitor AC power status and usage, act as a thermostat, turn the lights and the air compressor on and off, and anything else i dream up as i work on it.

the lights and compressor i will control with 2 Solid State Relays (AC, 25A). i will also have a sensor to monitor air compressor charge PSI. this is a 0-150PSI sensor that outputs 0-5Vdc analog.

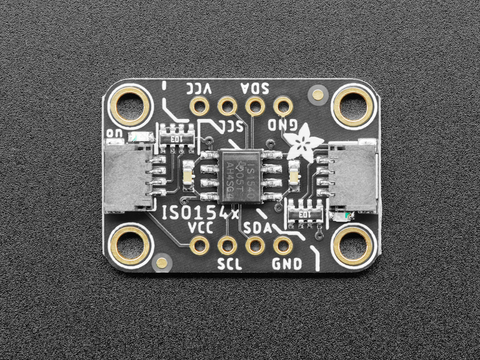

the thermostat outputs via a I2C controlled relay board, and uses a DHT11 sensor for temperature and humidity.

the controller will monitor AC power status and usage, act as a thermostat, turn the lights and the air compressor on and off, and anything else i dream up as i work on it.

the lights and compressor i will control with 2 Solid State Relays (AC, 25A). i will also have a sensor to monitor air compressor charge PSI. this is a 0-150PSI sensor that outputs 0-5Vdc analog.

the thermostat outputs via a I2C controlled relay board, and uses a DHT11 sensor for temperature and humidity.